2 Sensor Technology

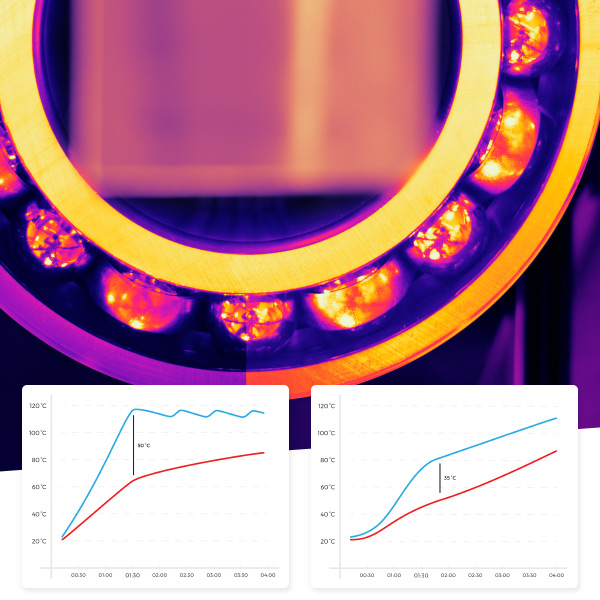

Stress-free heating is crucial to prevent material and mechanical tensions. Extreme tensions can damage a bearing or gear irreversibly and result in disfunction, breakdown, shorter lifespan of the specific part or even worse, the entire application. TM’s unique 2-Sensor Technology guarantees a fully controlled heating process.

Tailor-made Induction Heating Solutions

Developing and building special applications became a true specialty of TM Induction Heating since the start, back in 1992. Whether a modified application, a complete custom-built production machine or anything in between is needed; we build it.

Our special applications are used all over the world in various industries such as: Mining, Wind Power, Automation, Electromotors, Rolling Stock, Engines, Agriculture, Motion / Drive, Steel, and Aerospace.